Lithium mining Project Study Phase

Proactive Maintenance through Digital Thread: A Lifecycle Approach for Mechanical Drawings

Lithium mining Project-Study Phase

-

Streamlined process integrating Drafting & Engineering.

-

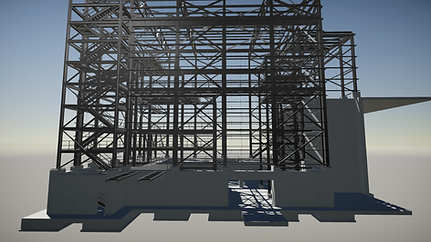

3D Modeling of the exiting building using Revit Autodesk

-

New equipment supports layout & clash detection using Navisworks.

-

750 Ton Structural steel design using STAAD Pro

-

Design of shallow foundation and concrete elevated slabs using RCDC (Bentley)

-

Design Of retaining wall using Staad Foundation.

-

Design Of Truss Connection using RAM Connect.

-

35% Saving in the engineering time resulting from tools and process integration.

-

Accurate Estimation of BoM at early stage of the project life.

Stress-free space organization system, guaranteed using our Crushing Area Designs

Model risk scenarios

Crushing Area Risk Quantification: This process prioritizes quantifying the likelihood and impact of potential disruptions within the crushing operation.

Increased Productivity

Minimizing clutter and implementing a well-organized equipment layout in the crushing area can significantly improve operational efficiency by reducing wasted time searching for tools and materials.

Reduced Time Wasted Searching

A designated equipment staging area with clear segregation for tools, spare parts, and consumables ensures efficient access and minimizes delays during maintenance activities.

Enhanced Safety

A well-organized shed with proper storage solutions minimizes these risks.

You Can Check The Details Here